Features

- Superb impact resistance

- Flame resistant types

- Excellent machinability

- Outstanding aesthetic attributes

- Simple to paint and glue (bond)

- Solid strength and stiffness

- Suitable for vacuum forming

- Grades compliant with FDA standards

- Cost efficient

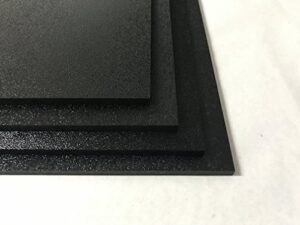

Colors

- Natural

- Black

- Custom (MOQ)