Features

- High mechanical strength

- Excellent electrical insulation properties

- Chemical resistance

- Low water absorption

- Thermal stability

- Machinability

Colors

- Natural

- Black

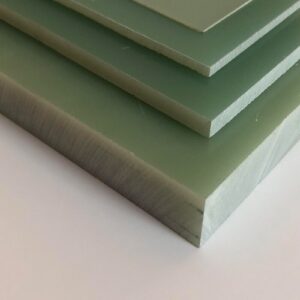

- Green

- Red

Features

Colors

Size Availability

Rod

Sheet

There is an extensive selection of Industrial Grade Laminates available in sheet, rod, tubing, and custom fabricated parts tailored to your specifications. These laminates typically incorporate a combination of at least two components: a reinforcing substrate and a thermoplastic resin binder. The manufacturing process involves curing the composite material under high temperature and pressure.

Various reinforcing substrates are utilized in the production, including options such as glass cloth, glass mat, filaments, canvas cotton fabric, linen cotton fabric, paper, graphite fabric, and others. The thermoplastic binder resin plays a crucial role in binding these layers together. Options for binder resins include epoxies, melamine, phenolics, polyesters, silicones, and other materials.

Grades

Fabrication and distribution of custom, precision-machined plastic components, assemblies, and displays.

HP ManufacturingPhone Number(216) 361-6500

Fax Number(216) 361-6508

No matter your plastic fabrication requirements, we’re ready to serve you.

Thanks for submitting your email address for a quote. To get the fastest response, please fill in the remaining information below, and we’ll get right back to you!