When it comes to versatile and widely used engineering plastics, Acrylonitrile Butadiene Styrene, or ABS plastic, is at the forefront for many applications. In this blog, we will delve into the properties of ABS plastic and explore its versatility in different fields.

- Structure and Composition

ABS plastic is a thermoplastic polymer made up of three primary monomers: acrylonitrile, butadiene, and styrene. The composition of these monomers influences the overall properties of ABS plastic. Acrylonitrile provides chemical resistance and heat stability, butadiene contributes to impact resistance, while styrene provides rigidity and processability. - Mechanical Strength and Impact Resistance

One of the standout properties of ABS plastic is its impressive mechanical strength. ABS exhibits good tensile strength, enabling it to withstand significant forces without deformation. Moreover, it possesses excellent impact resistance, making it ideal for applications where sudden impacts or shocks are common, such as protective gear, heavy equipment/industrial applications, some automotive or aerospace components and toys. - Thermal Stability and Heat Resistance

This type of plastic boasts good thermal stability, allowing it to maintain its structural integrity under moderate temperatures. It can withstand temperatures ranging from -20°C to 80°C (-4°F to 176°F) without significant degradation, making it suitable for various indoor and outdoor applications. However, it is worth noting that ABS starts to soften and deform at higher temperatures. - Chemical Resistance

ABS plastic demonstrates good resistance to a wide range of chemicals, including acids, alkalis and various organic solvents. This property makes it an excellent choice for applications that involve exposure to chemicals or corrosive substances, such as piping systems, chemical storage tanks and automotive components exposed to fuel or oils. - Electrical Insulation Properties

Another advantage of ABS plastic is its electrical insulation properties. It possesses excellent dielectric strength, meaning it can resist the flow of electric current, making it an ideal material for electrical enclosures, switches and connectors. ABS is also widely used in the production of consumer electronics due to its ability to insulate and protect sensitive electronic components. - Surface Finish and Aesthetic Appeal

This material also is known for its surface finish and aesthetic appeal. It is relatively easy to mold and process, allowing for the creation of intricate designs with precise details. Additionally, ABS can be easily painted, glued or printed upon, providing designers and manufacturers with more creative freedom in their product development processes. Its versatility in terms of color and texture makes ABS a preferred choice in consumer goods, such as appliances, computer hardware and consumer electronics. - Ease of Processing

ABS plastic’s ease of processing is another reason for its widespread use in various industries. It offers excellent dimensional stability, to ensure consistent and high-quality output during manufacturing processes.

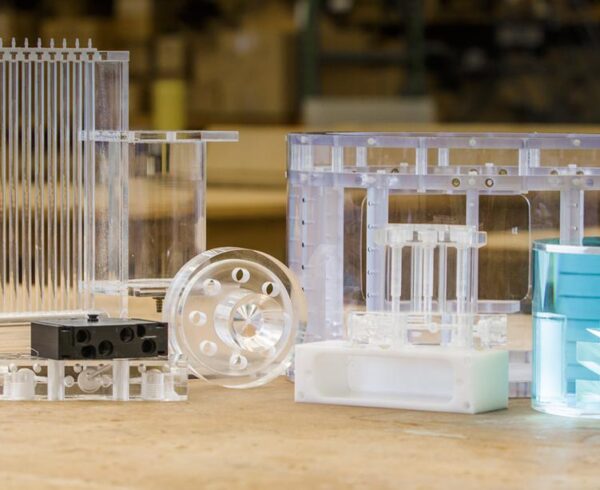

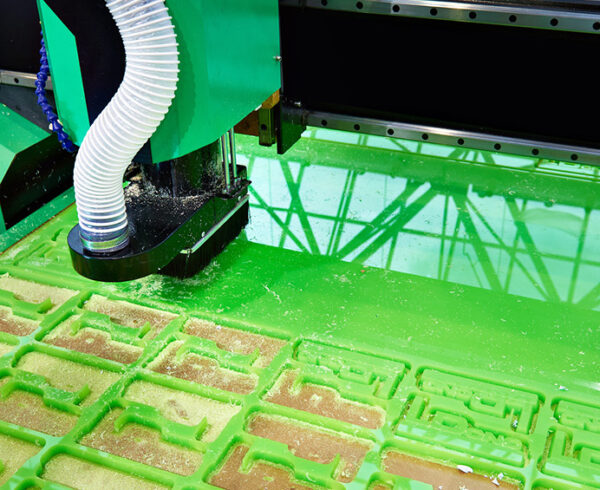

At HP Manufacturing we leverage state-of-the-art CNC machining equipment and advanced techniques to ensure precise and efficient fabricating and machining with ABS plastic. Our commitment to staying at the forefront of technology allows us to offer innovative solutions that satisfy specifications and exceed expectations.

By choosing HP Manufacturing as your partner, you gain access to our extensive capabilities. We have the expertise to handle complex ABS plastic projects, including intricate designs and tight tolerances. Our streamlined manufacturing processes and meticulous attention to detail ensure consistent quality and timely delivery. We also strive to strike a balance between product quality and project cost, to blend performance and value.

Conclusion

ABS plastic’s exceptional combination of properties makes it a go-to material for many industries. Its mechanical strength, impact resistance, thermal stability, chemical resistance, electrical insulation properties, and ease of processing have led to its utilization in a diverse range of applications. As technology advances, new opportunities continue to appear that can leverage the properties of ABS plastic or other advanced thermoplastics.

When it comes to optimizing the full potential of ABS plastic, partnering with a trusted and experienced manufacturer is essential. This is where HP Manufacturing stands out from the crowd. HP Manufacturing takes pride in delivering superior service. Rely on our team of skilled technicians and engineers for our in-depth knowledge working with plastics like ABS or other high-performance plastic materials.

Our machining capabilities cover a wide range of processes for plastic machining and fabrication for plastic fabrication, such as boring, turning, 3-, 4- and 5-axis milling, routing or reaming to engraving or flame polishing. With our superior expertise and dedication to delivering top-notch service, we ensure that whatever we manufacture delivers your specified precision and quality.

Call to discuss with us your next project. Whether ABS is the best material to meet your specifications or another type of plastic, allow us to help determine which material and CNC machining process will best suit your application. We work closely with our clients, providing tailored solutions and expert guidance throughout the manufacturing process. Call us, or go online to request a quote for your next project.