Mechanical plastics, otherwise known as engineering plastics, refer to plastics that are used in applications due to their mechanical nature or functionality, rather than their appearance. Many mechanical plastics can substitute for metal substrates which offers a cost savings and lighter weight materials without sacrificing durability.

When it comes to physical material requirements that require brawn over beauty, HP Manufacturing can recommend a mechanical plastic with the proper characteristics to match project specifications for a wide range of industries and applications that need strength and high wear resistance.

Strength and Resilience

Mechanical plastics offer superior strength and resilience compared to other types of commodity plastic materials. There is a broad range of mechanical plastics with varying characteristics. While most are lightweight, some can be heavy.

Mechanical plastics are commonly resistant to high impact, heat (on a varying scale) and chemical corrosion (although some have better chemical resistance than others). Industry applications will vary depending upon the type of engineering plastic, but can include healthcare, equipment manufacturing, electronics, transportation industries, food processing, and more.

Common mechanical plastics include:

- Nylon

- Acetal(Delrin)

- ABS

- PTFE

- PVC

- UHMW

- PVDF

- PEEK

- HDPE

Nylon

Nylon is a strong, stiff engineering plastic capable of replacing metal bearings and bushings. It has tremendous wear-resistance properties and often eliminates the need for external lubrication. Other material benefits of nylon include:

- Reduction in part weight

- Good strength- to- weight ratio

- Less operating noise

- Decreased wear on mating parts

In terms of applications, nylon is commonly used for wear pads, packaging machinery parts, and food processing parts. There are different subsets and brands of nylon. Ask our engineering department for the types of nylon that best fit your application.

Acetal

Acetal, commonly referred to by its brand name Delrin®, is known for its high strength, wide operating temperature range (-40°C to 120°C), and excellent mechanical properties. It is a stiff, low-friction engineering plastic with good wear properties in both wet and dry environments.

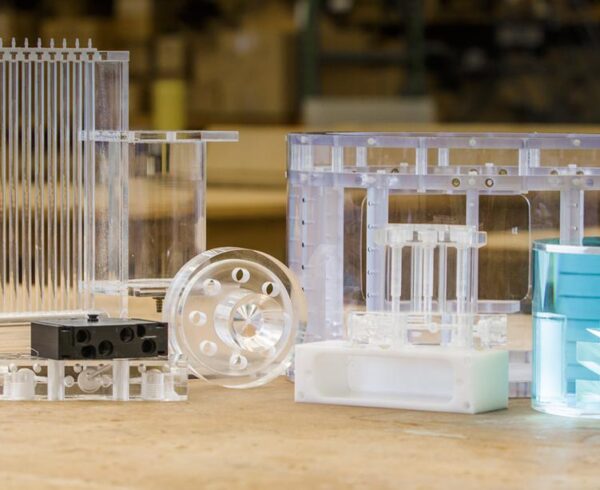

It is easily machinable, which makes acetal an excellent choice for parts with complex geometries and tight tolerances.

Other features of acetal include:

- Chemical resistance to hydrocarbons, solvents, and neutral chemicals

- Excellent creep resistance

- High tensile strength and rigidity

Common applications that call for acetal include pump and valve parts, food processing parts, wear pads, electrical components, and other high- wear applications. Wear pads are common in the equipment industry and would include anything with a surface that will see a lot of friction.

PTFE

PTFE is a low- friction engineering plastic with outstanding resistance to chemicals and weathering. This material is stable up to 500° F, which makes it a suitable choice for high- temperature environments. Other material characteristics of PTFE include:

- Low thermal conductivity

- Resistance to light and UV exposure

- Low coefficient of friction

- Good strength- to- weight ratio

Its excellent electrical insulating properties make PTFE a good choice for electrical components. It is widely used for seals, gaskets, wire insulation, semiconductor equipment, chemical- resistant tubes, and healthcare applications.

ABS

ABS is an economical engineering plastic that combines high- impact strength and rigidity with thermoforming capabilities. It is commonly used for machine housings, guards, and covers. In addition, ABS offers the following:

- Great impact resistance

- Easy machinability

- Easy to bond

- Surface hardness

- Good strength-to-weight ratio

These characteristics make ABS a popular choice for interior decorative automotive parts, computer components, protective housings for power tools, plastic toys or blocks, pipes, fittings, power tool housings, and 3D-printed building materials.

PVC

Rigid PVC is a low-cost material that is easy to fabricate and easy to bond. It offers properties similar to ABS but is also FDA approved. It offers good chemical resistance and superior fire-retardant properties. It also offers a low temperature resistance and electrical insulation characteristics.

There are different types of PVC that HP Manufacturing carries:

PVC Type I:

- Normal impact resistance

- Excellent corrosion and chemical resistance

- Good strength-to-weight ratio

PVC Type II:

- High impact resistance

- Excellent chemical and corrosion resistance

CPVC:

- High heat and corrosion resistance

- Outstanding flame and smoke properties

The physical properties of PVC are easily adjustable by adding modifiers that can help alter its flexibility or impact resistance, for example. Its variable physical characteristics and durability help make PVC an all-purpose mechanical plastic with potential use in multiple applications and industries.

UHMW

Ultra-high molecular weight (UHMW) polyethylene is strong and versatile. Although a lightweight material, it offers high abrasion impact and wear resistance. Other features of UHMW include:

- Strength and durability

- Low coefficient of friction

- Broad temperature range

- Ubiquitous usage across industries

- FDA approved

The most common use of UHMW is in the food processing industry for conveyor belts and rollers. It also is useful for wear pads due to its low coefficient of friction and high impact strength.

PVDF

Polyvinylidene fluoride (PVDF) is a low-density, strong, and stable mechanical plastic. Its thermoplastic capabilities enable fabrication of parts through either injection or compression molding. It offers high mechanical strength alongside good processability.

Other properties of PVDF are:

- Good electrical properties

- Low melting point

- High heat deflection temperature under load

- Low permeability to gases and liquids

- Wide range of melt flow rates

One of the most common uses for PVDF is within chemical processing parts and equipment such as tubes, pipes, valves, and fittings. Its electrical properties make it useful for wire and cable installations.

PEEK

PEEK is a high-performance engineering plastic with outstanding resistance to harsh chemicals and corrosion, excellent mechanical strength, and dimensional stability.

It also offers:

- High heat tolerance

- High tolerance to mechanical and physical stress

- Good fire performance

- Outstanding resistance to hydrolysis

- Autoclavability

PEEK is, however, one of the more expensive mechanical plastics. It is commonly found in the aerospace, oil and gas, food and beverage processing, and semiconductor industries, due to its proven track record in challenging environments. Of further note is its ability to maintain rigidity during continuous use at temperatures up to 338° F.

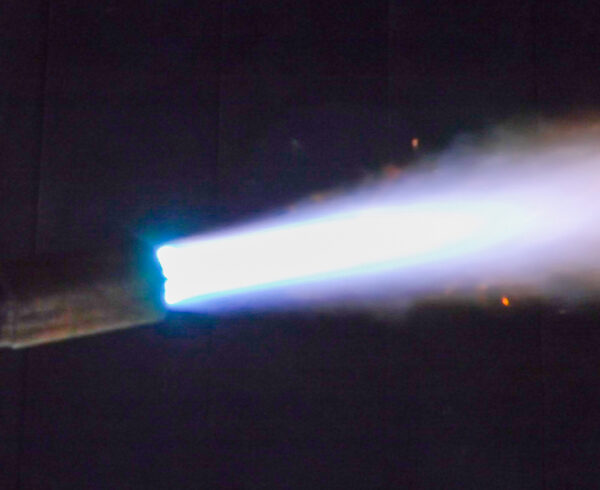

Other common applications include pump and valve components and medical instrumentation. PEEK is easy to machine and fabricate. It holds a UL 94 flammability rating at 0.059 inches. It also has very low smoke and toxic gas emissions when exposed to flames.

Why Choose HP Manufacturing for Mechanical Plastics?

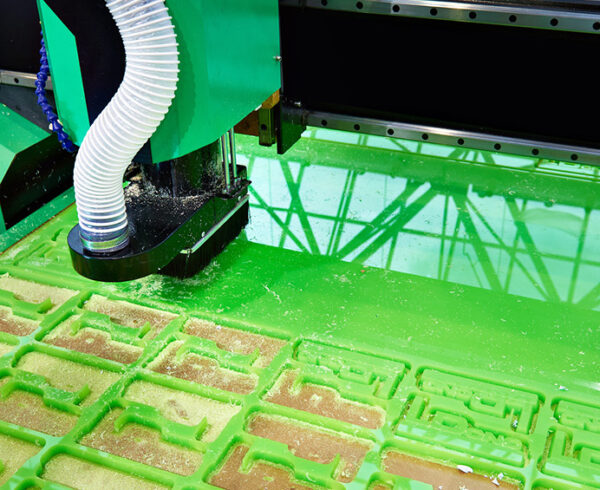

HP Manufacturing machines 90% of these mechanical or engineering plastics on a daily basis and stocks them onsite. Certain engineering plastics lend themselves more easily to machinability, while others due to a more brittle nature, require a slower machining process to protect the material integrity.

Due to its depth of experience and daily exposure to projects that use engineering plastics, HP Manufacturing can consult with clients to help select the material with the properties that will match project specifications.

Work with HP Manufacturing for excellent customer service, attention to detail, depth of knowledge, and experience working with all manner of plastics for industrial and medical purposes.