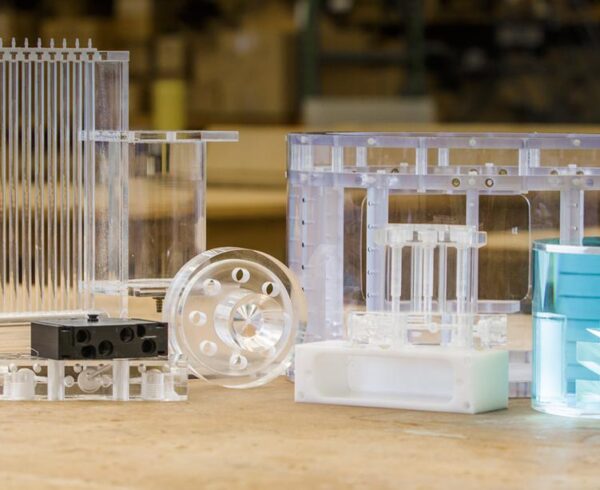

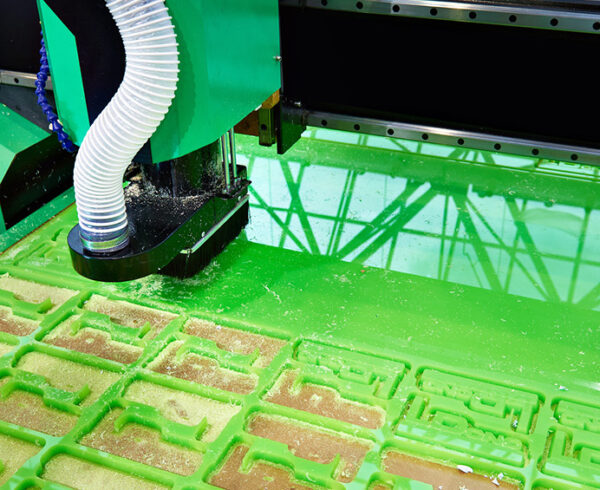

CNC machining is a popular method for manufacturing precision parts, and heat-resistant, high-performance plastics are often used in high-temperature applications where metal may not be suitable. In this blog, we will discuss the best heat-resistant plastics to use when CNC machining is involved.

- PEEK

PEEK (polyetheretherketone) is a high-performance thermoplastic that is widely used in aerospace, heavy industry, and medical industries. It has excellent heat resistance, with a melting point of around 343°C (649°F) and can maintain its mechanical properties at high temperatures. PEEK is also resistant to chemicals, abrasion and wear, making it an ideal material for CNC machining in harsh environments. - Vespel

Vespel is a family of high-performance polyimide materials that can withstand high temperatures up to 316°C (600°F). It is often used in applications such as bearings, seals and electrical insulation. Vespel has excellent wear resistance, low friction and good dimensional stability; so, it is an excellent choice for CNC machining in high-temperature and high-stress environments. - Torlon

Torlon is a high-performance amorphous thermoplastic that can withstand temperatures up to 288°C (550°F). It is often used in aerospace, heavy industrial and semiconductor applications where high strength and dimensional stability are required. Torlon has excellent chemical resistance, low moisture absorption and high stiffness, a particularly good fit for CNC machining in high-temperature and chemically aggressive environments. - Ultem

Ultem (polyetherimide) is a high-performance thermoplastic that can withstand temperatures up to 170°C (338°F) without degrading. It is often used in heavy industry, aerospace and electrical applications where dimensional stability and high strength are required. Ultem has excellent resistance to chemicals, UV radiation and electrical insulation; so, it is commonly used for harsh environment applications. - Teflon

Teflon (polytetrafluoroethylene) is a high-performance fluoropolymer that can withstand temperatures up to 260°C (500°F). It is often used in applications such as seals, gaskets and electrical insulation. Teflon has excellent chemical resistance, low friction and high dielectric strength; so, it is typically chosen for chemically aggressive and high-temperature environments.

As experts in custom precision machining of plastic components, HP Manufacturing has seen many projects over the years where the wrong material was specified. Here are the more common mistakes we’ve seen and the problems this could have caused:

- Not considering the specific requirements of the application

Different applications have different requirements for temperature resistance, chemical resistance and mechanical properties. - Overlooking the importance of dimensional stability

Heat-resistant plastics can be prone to dimensional changes when exposed to high temperatures, which can affect the precision of CNC machining. - Choosing a material solely based on its temperature resistance

While heat resistance is an essential property for many applications, it is not the only consideration. Other properties, such as chemical resistance, wear resistance and dimensional stability, may be just as important. - Neglecting the limitations of the CNC machining process

CNC machining has certain limitations, such as the ability to handle complex geometries and tight tolerances. - Not consulting with a plastic machining expert

Selecting the right heat-resistant plastic material for CNC machining can be challenging, and it is important to consult with a plastic machining expert. A knowledgeable expert can provide advice on material selection, machining techniques, and tolerances to ensure the best possible results.

While selecting the right heat-resistant plastic material for CNC machining can be challenging, we’re happy to collaborate with you during the engineering and design process as plastic machining experts. We regularly are called upon to provide advice on material selection, machining techniques, and tolerances to ensure the best possible results.