The rise of China, Vietnam, and their neighbors in Southeast Asia as a manufacturing powerhouse has been well documented. The ability to keep costs low, provide adequate management, and develop standard processes are factors that have made China and nearby countries seem to be the ideal location for many manufacturers, including plastics manufacturers. The idea of “going global” can be a very attractive one; however, things can change, and many manufacturers now are rethinking the advantages of importing materials and products from Asia.

Reshoring Problems: Material Availability, Labor Shortages, and Logistics

Material availability, labor shortages, and logistics are common problems faced by many plastics manufacturers that rely on Asian imports. Even before the COVID-19 pandemic, many plastics manufacturers faced long delays and quality issues when importing plastics materials from Asia.

Shoring Things Up: The Benefits of Reshoring from Asia

In recent years, some manufacturers have begun to recognize the benefits of re-shoring materials from Asia to North America, including to Mexico and Puerto Rico. Manufacturers may be influenced by high transportation costs, rising labor costs in the region, slow shipping times and other factors.

Controlling the quality control process

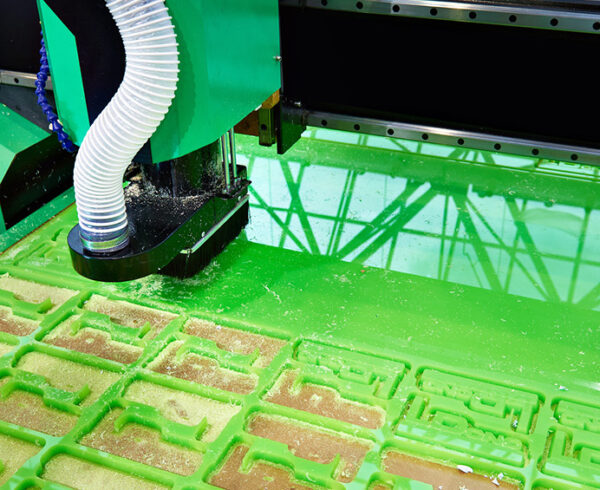

There are several benefits to reshoring manufacturing, including for plastics fabricators. For example, companies can set up their own quality controls and more easily monitor production when facilities are located domestically.

Higher quality is an important reason that companies are starting to look at domestic manufacturing. By working closely with a domestic supplier or bringing fabrication in-house, manufacturers have greater control and oversight of product quality.

Even if the quality issues from Asian manufacturers can be addressed, the timeline for fixing these issues can be long, which causes even more material shortfalls. To meet the demands of their customers, plastics manufacturers must build products to exact specifications that are machined to the highest possible tolerances. Parts must meet customer needs for specific tolerances, traceability, and other specifications—and that can only be assured by having control over the entire process.

Faster shipping and Made-in-the-USA labeling

They can also receive products and materials much faster than ordering from Asia. In addition, companies can save money through reshoring because, even though wages in Asia are traditionally lower, that has been changing. In fact, China, once labeled a low-cost country, or LCC, is no longer recognized as such by most organizations. Also, many companies prefer “Made in USA” products simply because that is what their customers prefer.

Bringing jobs back from Asia

Reshoring creates jobs in the United States, across many sectors, not just plastics manufacturing. Apple, for example, has committed to spending hundreds of millions of dollars to bring more manufacturing back to the U.S. and is projected to create tens of thousands of new jobs for Americans. The U.S. semiconductor industry is another example of a broad initiative to build new production fabs in this country rather than continuing to rely only on China, Taiwan, and other countries for critical chips needed to power our economy. By bringing manufacturing like this back to America, people have a chance to work at these new manufacturing facilities. Reshoring can also create jobs in other sectors of the economy, such as the service industry.

In-house fabrication for faster time-to-market

In the past, outsourcing was all about low-cost manufacturing, but as the total costs (not just raw material costs) from doing business in Asia increase and supply chain problems continue, time-to-market becomes even more important. Plastics manufacturers that bring fabrication back home can benefit from an overall cost decrease by maintaining greater control over their processes and quality and avoiding unnecessary budget overages.

Government incentives for reshoring

Government incentives also play a role in decisions to reshore manufacturing. Recent tax and other economic development policies encourage reshoring to increase tax revenues, enhance U.S. competitiveness, and create more American jobs.

Keeping It In-House and Keeping Customers Happy

There are many advantages to reshoring that may not always be obvious. By bringing manufacturing back home, plastics manufacturers get more control and oversight over their fabrication process. Re-shoring is an opportunity to improve customer satisfaction by being able to deliver on time and, ultimately, cut costs, which enhances their reputations and creates domestic jobs.

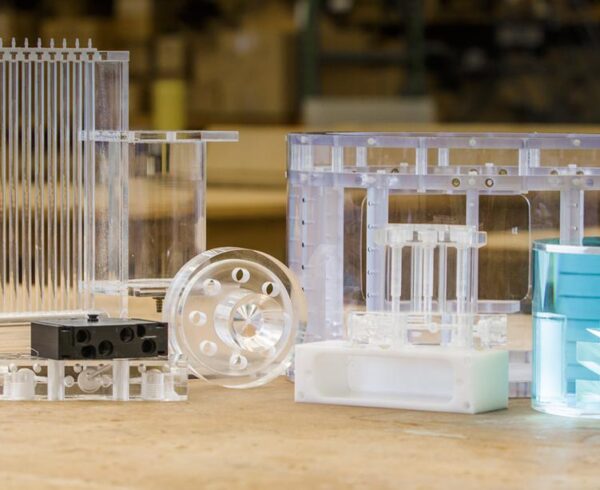

While many companies rely on offshoring their materials for plastics manufacturing, HP Manufacturing has never followed this model. We are not only a distributor of plastic materials, but we also perform our own machining and fabricating in-house, facilitated by teams of experienced workers. HP keeps materials in stock, which eliminates the wait time for critical supplies to be unloaded from docks and shipped across country, thereby ensuring that you get your products delivered on time within exact specs and tolerances.

From a labor standpoint, whether the shortages are caused by the pandemic or other socioeconomic reasons, even in a challenging hiring environment, HP Manufacturing strives to retain our experienced employees, who are experts in all facets of plastics manufacturing.

If you have questions about HP Manufacturing products or services, and how our in-house plastics fabrication can fulfill your needs, please contact HP Manufacturing. Our experts will be happy to help.