In the realm of modern materials, polycarbonates have carved a niche for themselves by combining exceptional qualities such as transparency, durability and impact resistance. This versatile thermoplastic is used in extensive applications across various industries, from automotive to electronics, owing to its unique properties. However, polycarbonate fabrication and machining presents a set of challenges that demand an expert machining partner. In this blog post, we will explore the remarkable properties that make polycarbonates sought-after materials, as well as the obstacles faced by engineers and designers when working with them.

Advantageous Attributes of Polycarbonates

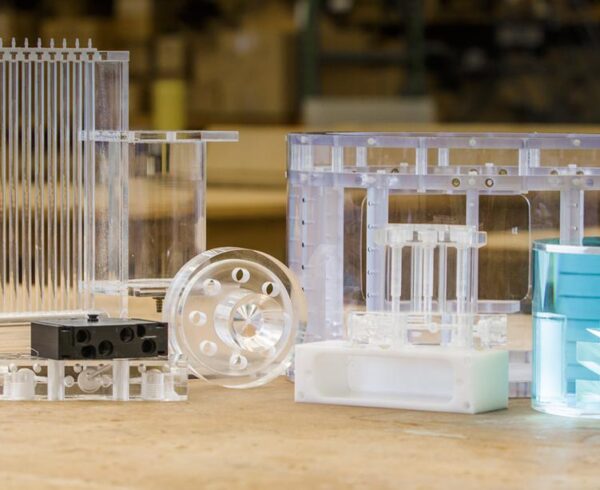

- Transparency and Optical Clarity: One of the standout features of polycarbonates is their excellent transparency. Unlike traditional plastics, polycarbonates offer exceptional optical clarity, making them an ideal choice for applications requiring unobstructed visibility. Whether used for the windows of an airplane or the protective cover of a smartphone, polycarbonates allow light to pass through with minimal distortion. This property makes them suitable for applications in the optical industry, where clarity and precision are paramount.

- Exceptional Durability and Impact Resistance: Polycarbonates possess outstanding durability and impact resistance, making them incredibly tough materials. They can withstand high forces without cracking or breaking. From safety helmets to bulletproof panels, polycarbonates provide a high level of impact protection. They can also withstand extreme temperatures, making them suitable for use in both hot and cold environments.

- Flame Resistance: Flame ratings for various polycarbonates are a measure of the material’s resistance to flame and its ability to self-extinguish. Polycarbonates typically have a UL94 flame rating, a standard that evaluates the materials burning characteristics. It is classified into different categories, such as V-0, V-1 and V-2, with V-0 being the highest rating. A V-0 rating means that the material self-extinguishes within 10 seconds of removing the flame, while V-1 and V-2 have longer durations. Polycarbonate’s flame ratings make it suitable for applications where fire safety is essential, such as in machines and assemblies that would require flames to be extinguished to minimize damage.

Challenges of Machining Polycarbonates

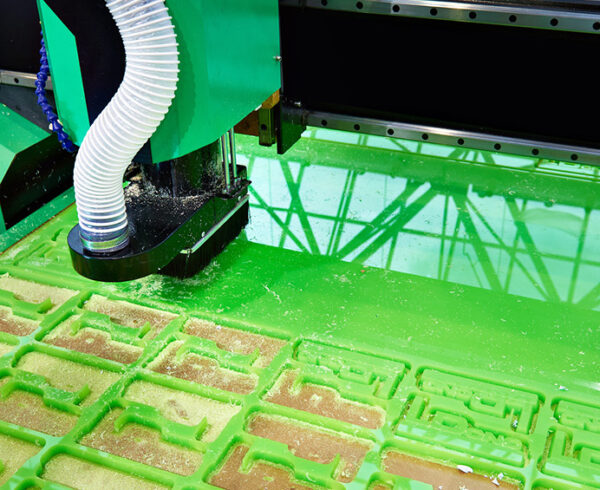

Fabricating custom parts and components from polycarbonates presents several challenges. Polycarbonates are known for their high strength, but they can be prone to warping, cracking and melting if not handled correctly. The material requires precise machining techniques and careful attention to temperature control. Additionally, while polycarbonates offer impressive strength, they can be prone to scratching because it is software than other plastics, necessitating careful handling and surface protection during processing and use. That’s why it is crucial to work with a team of experienced CNC machinists.

A benefit of it being software is that it allows for greater impact resistance. There is a naturally an engineering trade-off between scratching and impact resistance. In addition, there are scratch-resistant options available for polycarbonates.

The right CNC team will ensure proper programming, tool selection and machining parameters to achieve accurate and consistent results, thereby avoiding costly mistakes and ensuring the best quality end-product. A trusted machining partner will select the appropriate cutting tools, feeds and speeds to minimize the risk of material damage. Their expertise in handling polycarbonates ensures optimal dimensional accuracy, surface finish and overall product integrity. All this adds up to customer satisfaction and efficient production workflows.

Another significant challenge faced when working with polycarbonates is their relatively high coefficient of thermal expansion. This property can lead to dimensional changes during processing and temperature variations, potentially affecting the final product’s accuracy and performance. Special care must be taken to control and compensate for these thermal effects, such as employing custom fixtures and carefully controlling processing parameters.

Polycarbonates can be vulnerable to certain chemicals, including some solvents and cleaning agents. Exposure to these substances may lead to discoloration, embrittlement or loss of transparency. Therefore, it is crucial to consider the compatibility of polycarbonates with specific chemicals and select suitable alternatives or protective coatings when necessary.

Polycarbonates have undoubtedly earned their reputation as exceptional materials due to their transparency, durability, impact resistance and design versatility. However, working with polycarbonates presents a set of challenges that must be addressed to maximize their potential.

Finding the Right Partner for Your Polycarbonates Components

The technical team at HP Manufacturing works daily with polycarbonates and other specialty plastics and understands how to work around its processing challenges. By taking appropriate precautions during processing and handling, HP Manufacturing can fully leverage the remarkable properties of polycarbonates to create innovative and reliable products for our customers across diverse industries.

Contact HP Manufacturing today to quote your next project using polycarbonates or any other specialty plastic. We work to your tolerances and specifications and deliver your project on time and within budget.