Polyethylene thermoplastic, often referred to as PE, is one of the most widely used materials in the plastics industry. Its versatility, durability and affordability make it a popular choice for various applications. From packaging materials to automotive components, polyethylene has found its way into countless products we encounter in our daily lives. In this blog post, we will delve into the properties of polyethylene thermoplastic, explore the challenges associated with machining and fabricating it, and highlight the benefits of working with experienced plastic fabrication firms when dealing with this material.

Understanding Polyethylene Thermoplastic:

Polyethylene is a synthetic polymer that is characterized by its ability to become pliable and moldable when heated, and then solidify upon cooling. This property makes it a thermoplastic, which means it can be melted and reshaped multiple times without undergoing significant degradation. Among the various types of polyethylene, the most commonly used ones include high-density polyethylene (HDPE), low-density polyethylene (LDPE), and linear low-density polyethylene (LLDPE).

These characteristics make polyethylene a good option for industrial applications such as:

- Agricultural applications for greenhouses and irrigation components, due to its weather-resistant properties.

- Construction materials such as pipes and fittings found in underground plumbing systems and waterproofing applications, since it is resistant to chemicals, corrosion and moisture.

- Toys and sporting goods because of its durability.

- Automotive and aerospace components such as fuel tanks, trim and electrical insulators, as a result of its lightweight, impact resistance and chemical resistance properties.

- Medical products due to its hygienic nature, flexibility and non-reactive properties.

- Electrical insulators in component subassemblies, because of its electrical insulation, mechanical strength and resistance to environmental factors.

- Recyclable containers such as recycling or storage bins and containers.

- Consumer goods ranging from household items to furniture to appliances. Polyethylene can be fabricated and machined into different shapes and sizes relatively easily.

Challenges in Machining and Fabricating Polyethylene:

While polyethylene offers numerous advantages, it also presents certain challenges when it comes to machining and fabricating. One of the primary difficulties is its low melting point. Polyethylene has a relatively low softening temperature, which means it can melt and deform under high temperatures encountered during machining processes. Consequently, this can lead to poor surface finishes, dimensional inaccuracies and even material degradation.

Another challenge lies in the material’s low coefficient of friction. This characteristic can cause issues during machining operations, such as poor chip evacuation, increased heat generation and the tendency for the material to stick to cutting tools. Additionally, polyethylene has a relatively high thermal expansion coefficient, which can result in dimensional changes and warping when exposed to heat.

Working with the Right Custom Fabrication Manufacturer

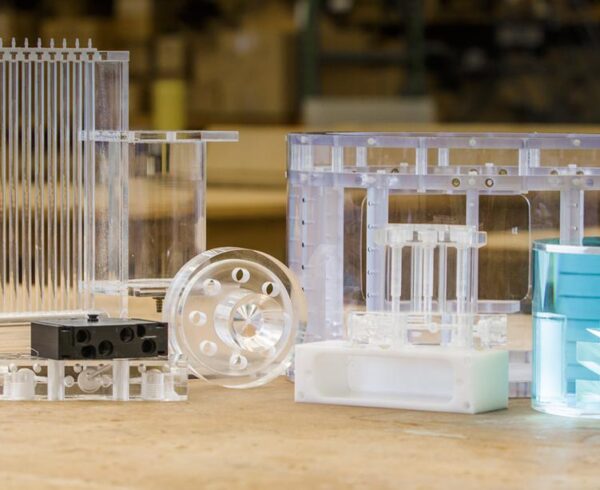

To overcome the challenges associated with machining and fabricating polyethylene thermoplastic, it is crucial to collaborate with an experienced plastic fabricator with the expertise, knowledge, and specialized equipment required to navigate the complexities of working with polyethylene effectively. At HP Manufacturing, our teams of technicians and engineers have many years of experience partnering with design engineers to ensure their components, regardless of plastic material, are produced to the exact specifications, to the tightest tolerances, that are required for many applications.

Here are some key benefits we bring to the table at HP as an experienced plastics machining partner:

- Material Selection Guidance: We can provide invaluable guidance in selecting the most suitable type of polyethylene for specific applications, identifying the optimal grade based on factors such as mechanical properties, chemical resistance, and environmental considerations.

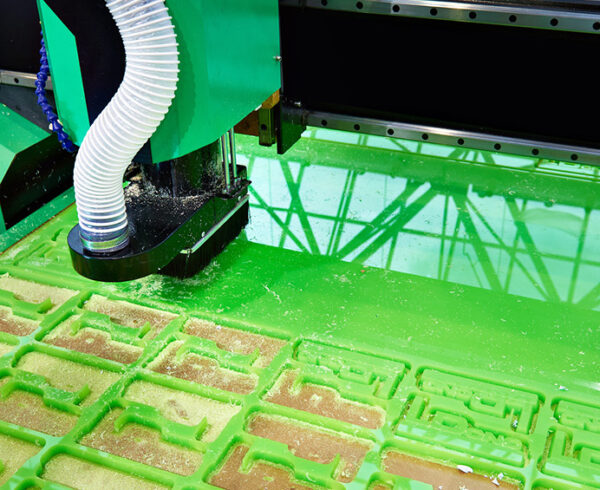

- Machining Expertise: With a deep understanding of polyethylene, HP has the know-how to choose the right machining techniques, tools and cutting parameters to achieve precise and high-quality results. We can minimize the challenges related to melting, poor surface finish and dimensional inaccuracies.

- Customized Fabrication Solutions: As a custom manufacturer, HP can develop tailored fabrication solutions to meet unique requirements. Whether it’s CNC machining, thermoforming or other techniques, HP staff can optimize the manufacturing process and ensure the desired outcomes.

- Quality Assurance: Working with HP ensures adherence to stringent quality control measures. We have the necessary testing capabilities to verify the mechanical properties, dimensional accuracy, and overall performance of the fabricated polyethylene components.

Polyethylene thermoplastic is a versatile material with a wide range of applications. Despite the challenges it presents in machining and fabrication, these obstacles can be overcome with the expertise and capabilities of an experienced plastic fabricator like HP Manufacturing. From material selection to customized fabrication solutions, collaborating with these specialists ensures optimal results and high-quality polyethylene components. Contact us today to discuss your upcoming project designs.