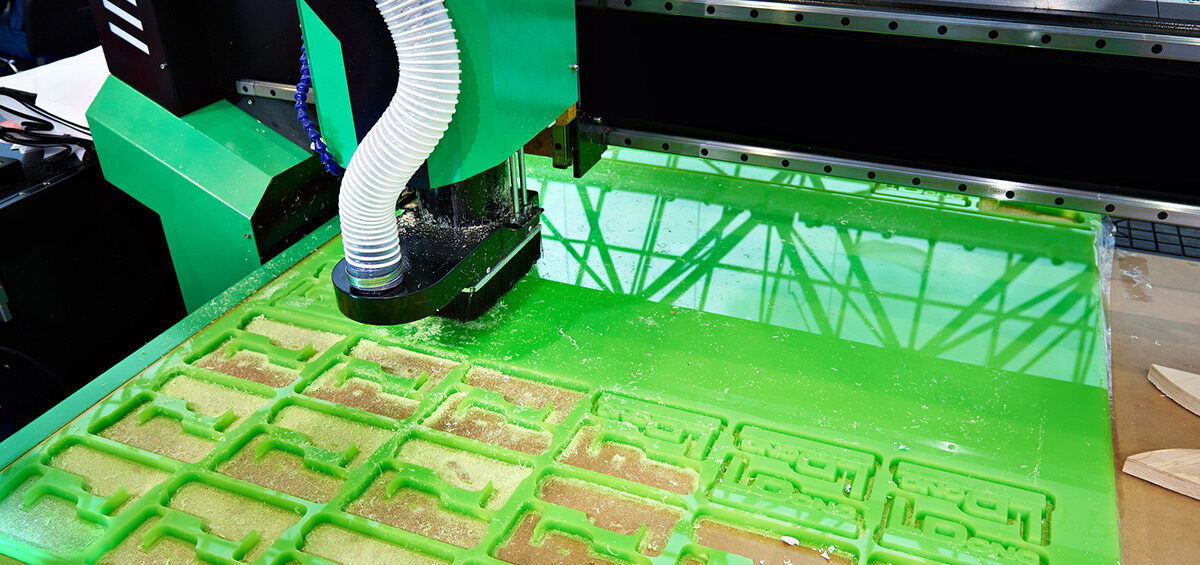

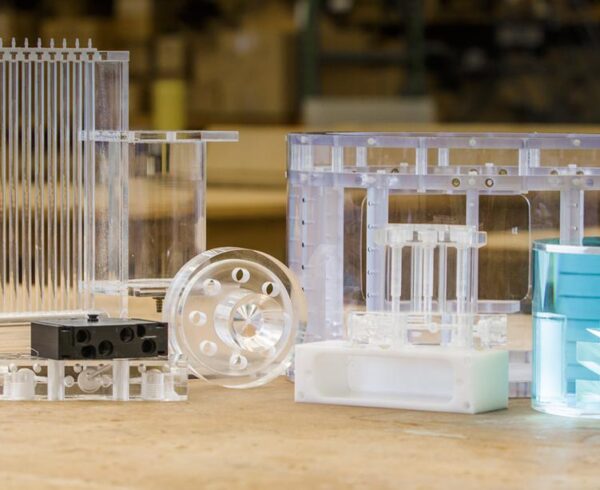

Plastic machined parts are widely used in different industries for various applications, from medical devices to heavy equipment components. However, not all plastic materials are easy to machine, and choosing the right material can be critical for the quality and cost of the final product. In this blog, we will discuss some tips on how to select easy-to-machine plastic materials for parts.

- Consider the Machinability of the Material

The machinability of a material refers to its ease of cutting, drilling and shaping during the machining process. Some plastics are easier to machine than others; so, the machinability of a material can be affected by various factors, such as its hardness, thermal conductivity and chemical resistance. The geometry of the part also can affect the machinability of the material. For example, parts with complex geometries may require more precise machining techniques and may require a material with better dimensional stability. Making a mistake here can lead to longer machining times, higher costs and lower-quality parts. - Look For Materials with Low Melting Points

Plastics with low melting points are generally easier to machine, as they require less heat and energy to cut and shape. Some examples of plastics with low melting points include Acetal (Delrin), UHMW Polyethylene and Nylon. These materials are commonly used in applications that require high wear resistance and low friction, such as bearings and gears. - Check The Moisture Content of the Material

The moisture content of a plastic material can affect its machinability and dimensional stability. Moisture can cause the material to swell or shrink, which can result in inaccuracies in the machining process. At HP Manufacturing, we discuss this factor often with our clients, as the types of projects we receive typically require machining to very tight tolerances. Some plastics, such as acrylic and polycarbonate, are hygroscopic, which means they absorb moisture from the air. It is important to store these materials in a dry environment and to check their moisture content before machining. Some parts of the country are more humid than others, of course, so decisions on plastic material should vary based on where the machining tasks will be performed. Some plastics may degrade or become brittle under certain environmental conditions, such as exposure to sunlight or chemicals. Ignoring these conditions can result in premature failure of the part. - Consider the Chemical Resistance of the Material

Some plastic materials are resistant to chemicals, which can make them difficult to machine. For example, PTFE (Teflon) is highly resistant to chemical attack, which makes it ideal for many applications yet requires us to use specialized machining techniques and equipment during production. On the other hand, materials such as PVC and polycarbonate are more easily machined but have lower chemical resistance. - Avoid Selecting a Material Based Solely on Cost

While cost is an important factor, selecting a material solely based on its price can lead to poor performance and higher costs in the long run. - Consult with a Plastic Machining Expert

Selecting the right plastic material for your application can be challenging, and it is important to consult with a plastic machining expert such as HP Manufacturing. As knowledgeable experts who have worked on thousands of precision machining projects, HP can help you choose the best material for your application based on factors such as cost, strength, machinability and chemical resistance. Additionally, we can provide advice on machining techniques and tolerances to ensure the best possible results.