Performance plastics, also known as high-performance polymers, are a type of plastic material that is designed to have superior physical and chemical properties compared to traditional plastics. They have a wide range of applications in various industries, including heavy equipment, aerospace, electronics, medical and more.

One of the key benefits of performance plastics is their ability to withstand harsh environments, which makes them ideal for use in high-stress applications. They are highly resistant to heat, chemicals, and offer great wear resistance. In addition, performance plastics are also lightweight, yet strong and durable, which makes them ideal for use in applications where weight reduction is a critical factor, such as in the aerospace industry.

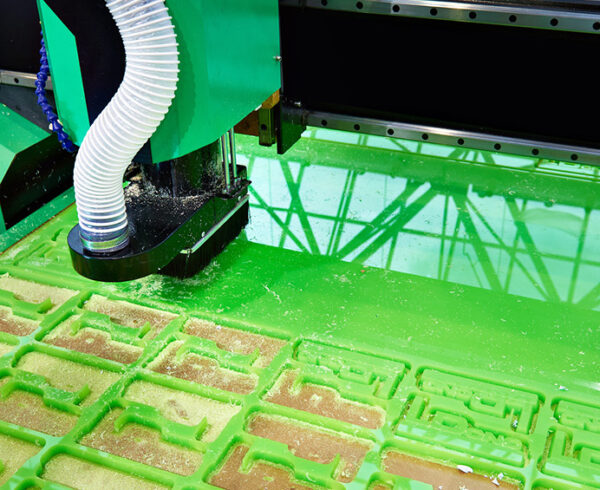

For instance, at HP we recently worked on a component intended for a rather harsh military application. This unit was contained in the housing of an underwater vehicle detection system, which would of course find its way to the deepest parts of the ocean. As a result, it would need to withstand extreme pressure and heat (because it was located near the engine room). Our engineers recommended to the client that we use HDPE material, since it can be easily machined and has excellent tensile strength as compared to other substitutes.

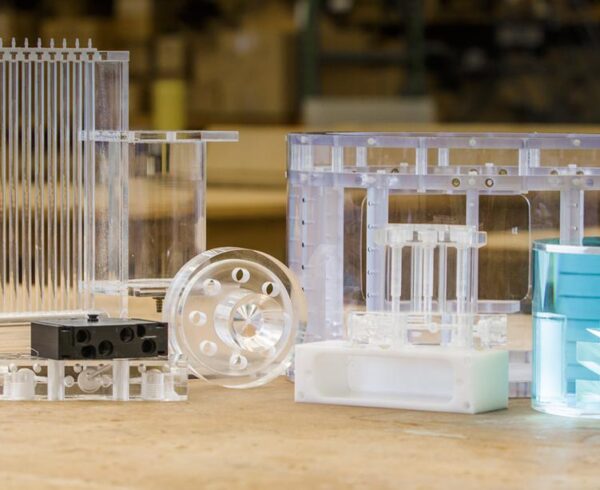

We see the same rugged demands placed on the plastic components we fabricate for medical diagnostic imagers. For examples, some “phantoms” we produce for these nuclear imaging systems must withstand nuclear-level exposure, since their work sometimes requires that they hold radioactive vials of materials. We recommend acrylics for this application, because it’s both cost-effective and it provides the ease of machining and fabricating for this application.

Another major advantage of performance plastics is their high resistance to wear and tear. This makes them ideal for use in applications where parts need to maintain their integrity and functionality during a long period of time, such as in the heavy equipment and aerospace industries. In addition, there are many performance plastics that are also self-lubricating, which reduces the need for additional lubricants and decreases friction-related wear and tear.

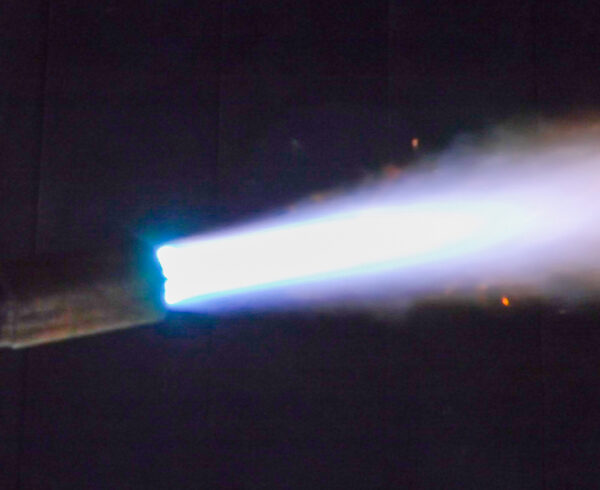

For instance, we relied on an oil-impregnated sheet of nylon for a recent heavy equipment project and chose Nylatron® NSM that effectively would lubricate itself. This material worked well for the client since it offers strong load-bearing capabilities while maintaining the impact resistance we’d expect from a nylon material. Performance plastics also have excellent electrical insulation properties, which makes them well-suited for use in the electronics industry. They are also highly resistant to electrical and thermal breakdown; so, they’re particularly effective for high-temperature applications. We recently were called upon to fabricate a high-voltage electric component for an electrical subway application. The voltage moving through the plastic component was truly massive in this instance; so, we chose ULTEM and GPO-III material for its resistance to weather and its electrical insulation properties.

In terms of environmental sustainability, performance plastics are highly recyclable and can be melted and reformed into new products. This reduces waste and helps to conserve natural resources. Additionally, due to their superior performance as compared to many metals their carbon footprint is lower due to the reduction in replacing metal parts. In other words, the plastic parts are outperforming and outliving their metal equivalents.

Overall, performance plastics are an increasingly popular choice for design engineers to spec for a wide range of applications due to their superior physical and chemical properties. They offer a range of benefits, including high resistance to harsh environments and wear and tear, excellent electrical insulation properties, and environmental sustainability. Cost is a consideration for these projects to keep in mind, however. These materials are expensive; so, mistakes made in routine fabrication or machining can create extra cost to the client in waste and scrap. At HP Manufacturing, our team works with these high-performance materials every day; so, we’re familiar with how they behave and react in our equipment during machining and fabrication operations. This can even vary during different weather temperatures and humidities; so, experienced operators are critical for getting the most out of performance-plastic projects.

Even so, as technology continues to advance, it is likely that we will see more applications for performance plastics in the future.