Delrin and Lexan are two popular plastic materials used in the manufacturing of plastic components, and we work with both on many projects at HP Manufacturing. While each has excellent mechanical properties and is widely used in various industries, the question is often asked of us — are they easy to machine?

Delrin is a brand name for a type of acetal plastic, also known as polyoxymethylene (POM). It is a thermoplastic material that is widely used in various industries for applications such as gears, bearings and other precision parts.

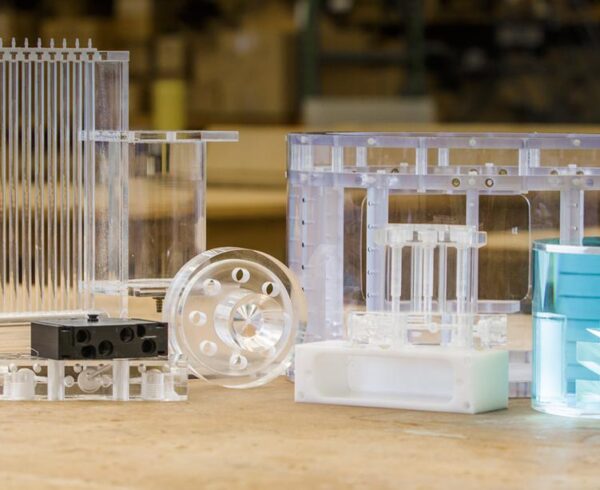

It is a tough, durable material that has excellent dimensional stability and resistance to wear and abrasion. When it comes to machining, Delrin is considered to be relatively easy to machine due to its low coefficient of friction. It is a homogenous material, and the finished parts typically can be produced to a high level of precision.

Lexan is a brand name for a type of polycarbonate plastic. It is known for its excellent impact resistance and optical clarity and is often used for windows, signs and safety shields.

Lexan is not as easy to machine as Delrin due to its brittleness, although it is still a popular material among many of our clients for CNC machining.

When it comes to the ease of machining Delrin and Lexan, several factors need to be considered:

- Machinability

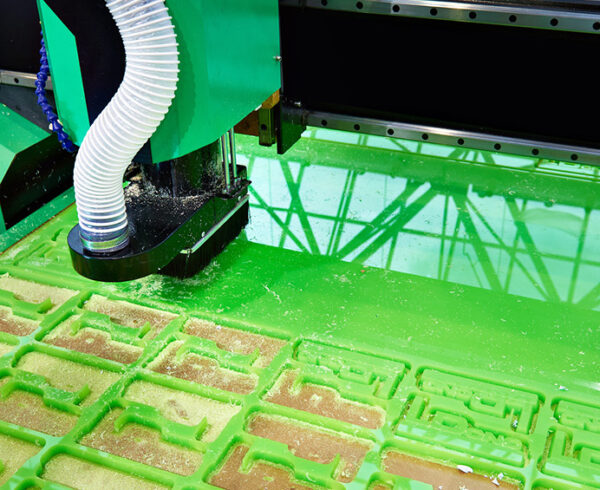

Delrin has excellent machinability, while Lexan is not as easy to machine due to its brittleness. Lexan has a higher risk of cracking and chipping during machining; so, it is essential to use appropriate tooling and machining techniques to prevent damage to the material. - Heat sensitivity

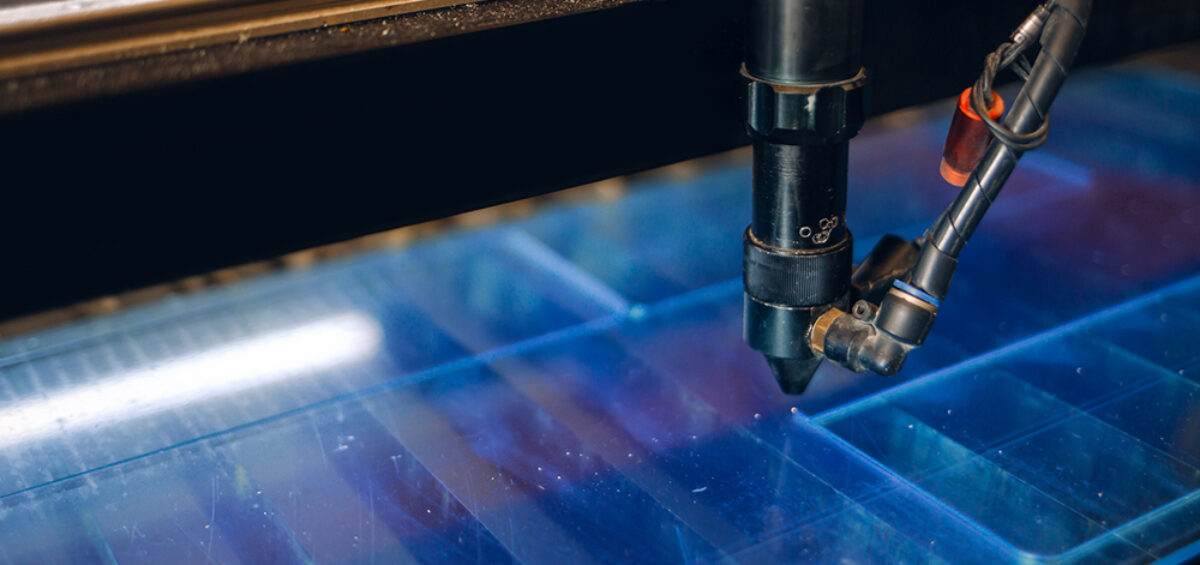

Both Delrin and Lexan are sensitive to high temperatures, which can cause melting or deformation during machining. We make sure to use the correct machining speeds and feeds to prevent heat buildup. - Tolerances

Delrin has excellent dimensional stability, which makes it suitable for parts with tight tolerances. Lexan, on the other hand, may require more attention to achieve the desired tolerances. - Part geometry

The geometry of the part can also affect the ease of machining. Parts with complex geometries may require more advanced machining techniques and may be more challenging to machine.

Both materials can be machined with the appropriate techniques and tooling. When selecting the best material for your plastic component, it is essential to find an experienced machining and fabrication partner who is experienced in using these and other plastic materials to produce your components with the precision and tolerances you require.