Finding the right custom plastic machining and fabrication partner is critical to the success of your project. Whether you need precision components for aerospace, medical devices, industrial equipment, or defense applications, your machining partner should offer more than just basic capabilities; They should bring expertise, certifications, and reliability to the table.

At HP Manufacturing, we help companies across industries transform their designs into durable, high-performance plastic components. Here are five things you should know before choosing a CNC plastic machining and fabrication partner.

- Specialized Experience With Engineering Plastics

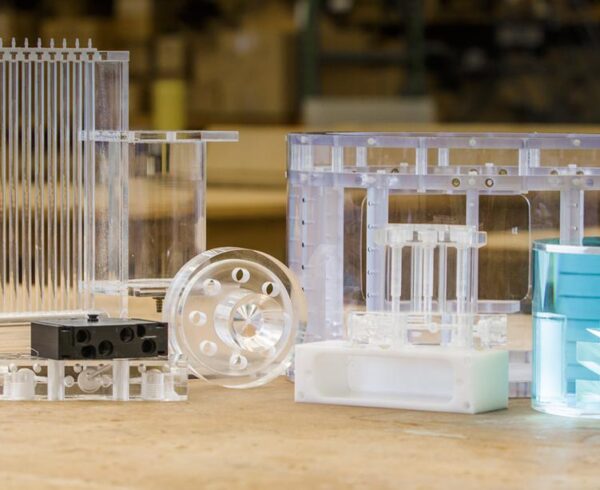

Plastic machining isn’t the same as metal machining. Engineering plastics like PEEK, Ultem, Delrin, and PVC behave differently under heat and stress. Without the right tooling and expertise, parts can warp, crack, or lose dimensional accuracy.

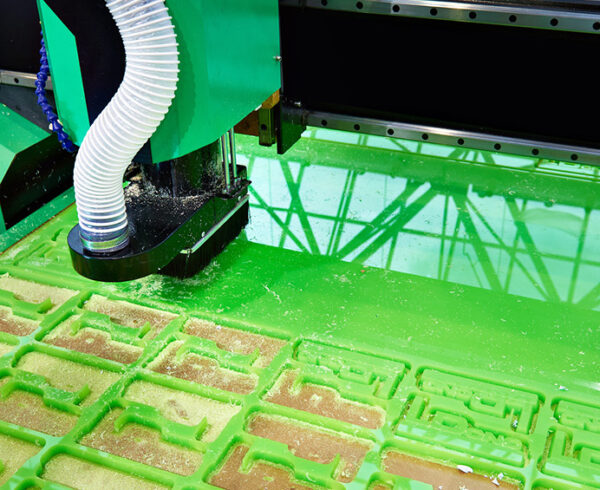

At HP Manufacturing, our team specializes in CNC plastic machining and fabrication, using advanced equipment and proven processes to achieve precision and repeatability, even with challenging materials.

- Certified and Traceable Materials

High-quality parts start with high-quality materials. Industries such as aerospace, defense, and medical manufacturing require certified, traceable materials that meet strict compliance standards.

HP Manufacturing sources plastics only from trusted suppliers all over the world and provides full material certifications, including FDA, RoHS, and AS9100 compliance. This ensures every part meets industry regulations and client expectations.

- Precision Tolerances and Quality Assurance

When performance and safety are on the line, tolerances matter. Our ISO 9001-certified quality management system ensures every part meets exact specifications. We use advanced inspection equipment and tight process controls to deliver consistent results, whether it’s a one-off prototype or a high-volume production run.

By combining precision machining and fabrication with rigorous quality assurance, HP Manufacturing helps customers reduce risk and avoid costly delays.

- From Prototype to Production

Your machining partner should support you through every stage of development. HP Manufacturing offers rapid prototyping services to validate designs quickly, followed by scalable production capabilities to meet long-term demand.

We also provide secondary services such as finishing, assembly, and packaging, streamlining your supply chain by keeping critical steps under one roof.

- Responsive Communication and Support

The best machining partner isn’t just a vendor, they’re a collaborator. At HP Manufacturing, we pride ourselves on clear, responsive communication. From fast quoting to design-for-manufacturing (DFM) feedback, we help our customers identify cost-saving opportunities while ensuring projects stay on track.

Why Choose HP Manufacturing as Your Custom Plastic Machining Partner?

Selecting a machining and fabrication partner is about more than comparing quotes, it’s about finding a team that understands your industry, delivers consistent results, and provides long-term support.

At HP Manufacturing, we bring:

- 86+ years of operational experience in custom plastic machining and fabrication

- Certified compliance for aerospace, medical, and industrial applications

- State-of-the-art CNC machining equipment

- A client-first approach that prioritizes reliability and communication

If you’re ready to take your next project from concept to reality, contact HP Manufacturing today. We’ll help you achieve precision, compliance, and scalability, every step of the way.